PROJECTS

Often, clients come to us with just an idea of the product or equipment they need in mind. They want a functional item but don’t want to dive into the complexities of design and manufacturing. That’s where we come in. We will create the product design, source the best components, handle the design process, and take full responsibility for all stages of production. We will also take care of delivery and installation. Here, you will find descriptions of some of our most interesting completed projects.

ADVANTAGES

REGULAR CONTACT

Starting from the first contact, throughout the entire project process, and ending with order delivery and service, you can rely on us.

Customized services

By implementing your ideas, we can customize the product down to the smallest details.

Automation solutions

Industrial manufacturing processes are moving towards automation, and we actively follow the trends. We base our services on innovations.

Qualified personnel

We have strict criteria for both our employees and temporarily hired specialists.

Implemented projects

CATEGORY: Agriculture

DATE: 2024

CLIENT: Farmer

SERVICES: Design, production, delivery

Frost fan

The task was to design a system capable of blowing off frost that forms over blueberry fields. This is a very impressive device. The fan itself is 37 kW, and the structure can move up and down, rotate around its axis, and adjust its angle. The device is delivered to the desired location, turned on, adjusted, and left to operate autonomously, as it starts running on its own based on the set temperatures. We hired partners for the design and automation. The production and assembly were carried out in-house. After the first season, the client reported that the idea proved to be successful.

CATEGORY: Design

DATE: 2018

CLIENT: UAB Videoprojektai LT

SERVICES: Design, production, installation

BELL

First of all, we would like to thank the client who entrusted such a project to a young company at that time. The task: to design and manufacture a bell structure that would be used during the centennial event of restored Lithuania and later stand for a month in Vilnius Cathedral Square. The design was developed together with the client, and then we designed the structure (currently, we no longer design projects of this scale ourselves). Now we can simply say: we designed, produced, and installed it, but back then, it was a project that really required a lot of challenges and work hours.

CATEGORY: Food industry

DATE: 2017

CLIENT: Asociacija “Penktas regionas”

SERVICES: Design, production, installation

DRYER

This was our very first completed project. Although we later produced four more industrial food dryers, this one remains the most memorable because it was a very interesting challenge: to create a dryer that would be as cost-effective as possible, with the project budget being very limited. Many decisions were made to reduce both the operating costs and the cost of the product itself. The heating system of the dryer is a hybrid one, allowing it to be heated with either wood or electricity. Instead of expensive heating radiators, we used car radiators. To save energy, we designed and manufactured a recuperator ourselves. After researching the regulations, we discovered that there could be preferential conditions for drying herbs, so where possible, we used wood (for the drawer frames). This dryer was filmed for the “Svajonių ūkis” TV show (Episode aired on 2018-06-02). While working on this website, we visited the client – it was great to see that the dryer has been in use for 7 seasons and looks set to continue to be used successfully.

CATEGORY: Industry

DATE: 2022

CLIENT: Private project

SERVICES: Design, production

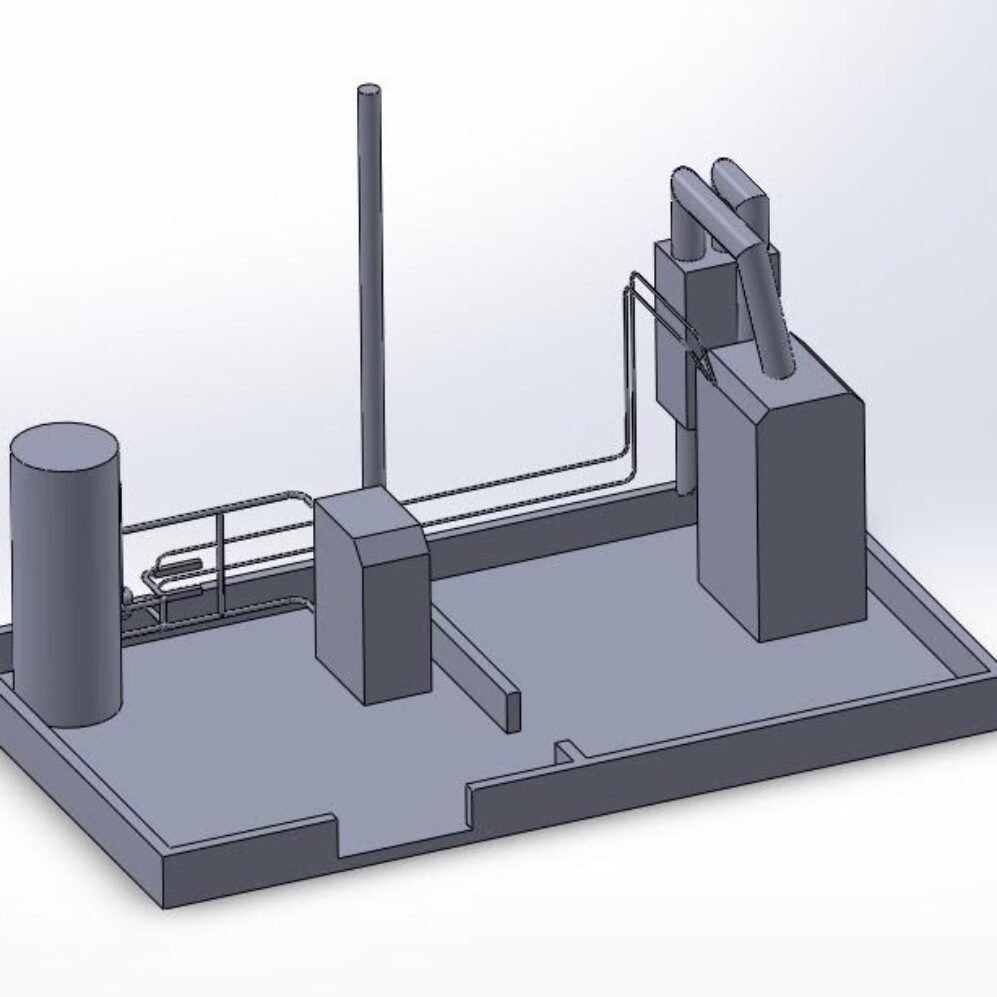

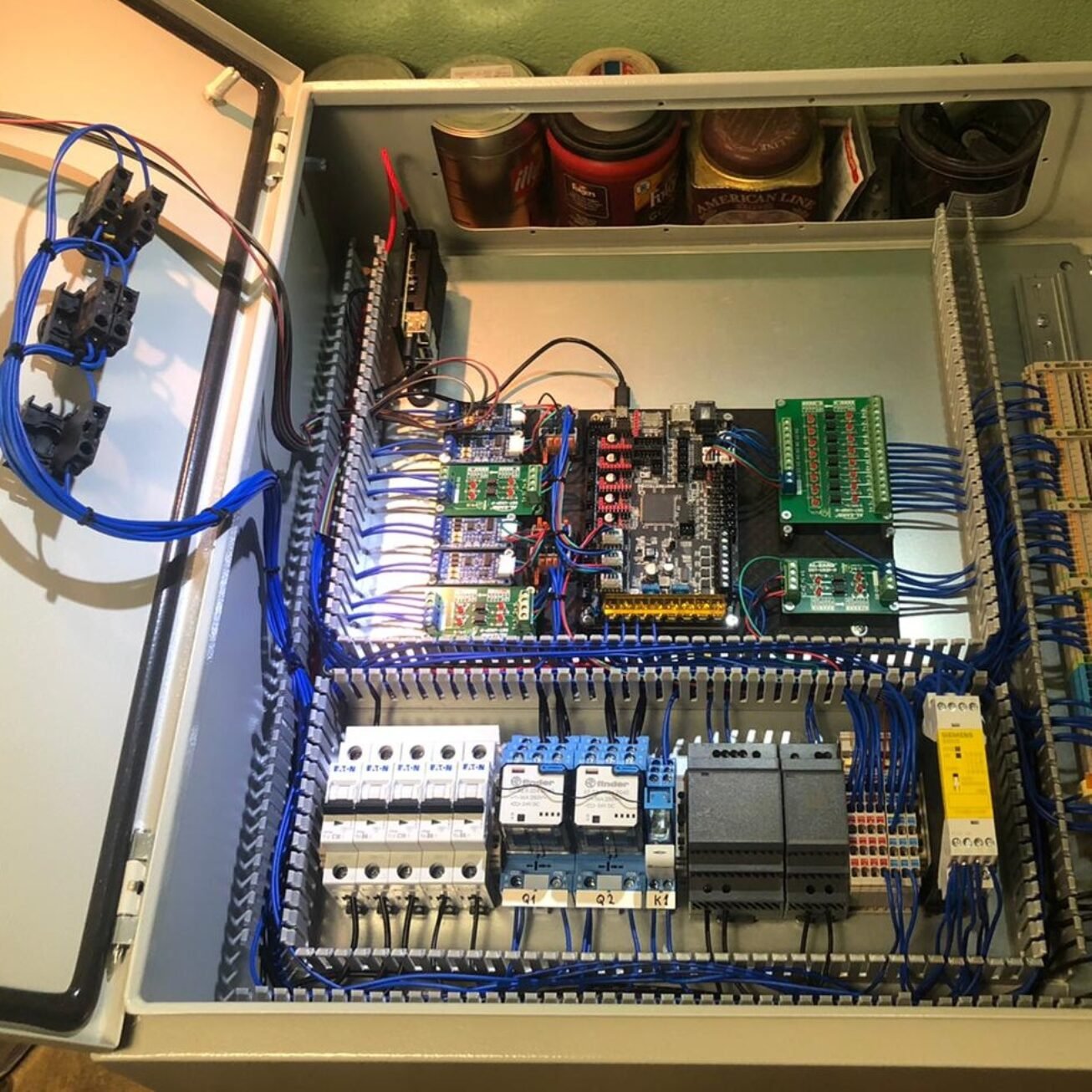

CNC PLASMA

An opportunity arose to purchase very old, yet still functional, ESAB Combirex CXL-P 2500 machines from 1988 at the price of scrap metal. We bought them without being sure if we would even use them. Later, after evaluating their condition, calculating the costs, and carefully considering everything, we decided to undertake their refurbishment. The machines themselves required almost no modifications, only a new table was built. However, the entire electronic system was radically upgraded: everything from the servo drives to the control cabinets was replaced. The plasma source was also replaced with a new one from the HYPERTHERM manufacturer. The machines are still in use today.

CATEGORY: Industry

DATE: 2021

CLIENT: Private project

SERVICES: Design, production

POWDER COATING

When we decided to set up a powder coating booth, there was a lot of discussion about whether to build it ourselves or buy one. The biggest advantage of building it ourselves was that we could install the booth in a location where the space wouldn’t be used for anything else. The downside was that we had no experience with powder coating, but challenges have never been something that stopped us. We designed and built the booth and the air ventilation system ourselves, and for the automation, we hired a partner we’ve worked with on multiple projects. The booth has been running at full capacity to this day.

CATEGORY: Entertainment

DATE: 2016

CLIENT: Ceased operations

SERVICES: Design, planning, production

SHIP

At that time, according to Lithuanian laws, it was mandatory to register all boats with gasoline engines, and the boat captain had to have a license. The client ordered a boat that, according to the then regulations, could accommodate up to 10 people (6 comfortably) and could be rented out as a canoe without any additional requirements. Moreover, the project budget was very limited. However, by using unconventional solutions and an electric motor, we successfully solved the task. After a few years of renting, the client ceased operations.

CATEGORY: Design

DATE: 2022

CLIENT: DHL Lietuva

SERVICES: Design, production, installation

BICYCLE RACK

The client requested a design, engineering, and production of a bicycle shelter that would also serve a representative function, as it would be located near newly built facilities, by the main entrance. The first design proposal was well received by the client, and after signing the contract, the work began. For the design, we hired a company that calculated the load and created the blueprints. To make the shelter durable, it was galvanized and powder-coated. It can be seen at Vilnius Airport, next to the client’s building.